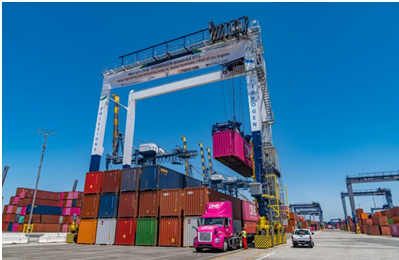

Mitsui E&S developed the H2-ZE

Transtainer crane and announced its completion at the Mitsui Oita factory in

April 2023.

During

development, it was verified that the same operational performance as the

conventional diesel-powered Transtainer cranes can be achieved, Mitsui claimed,

adding that for this project, a newly built H2-ZE Transtainer was delivered to

Yusen Terminals and entered into commercial operation to validate data taken

during the development phase for future improvements.

According

to Mitsui, ports which serve as global logistics hubs are large emitters of CO2

and toxic substances from diesel exhaust and are actively looking for solutions

to eliminate emissions. The Ports of Los

Angeles and Long Beach aim to eliminate emissions of all cargo handling

equipment by 2030.

“The use of hydrogen allows the H2-ZE Transtainer

cranes to produce zero emissions without connecting to the electric grid,

enabling the terminal operators to save on civil work investment and not impact

current operating procedures. Modification

of diesel powered RTGs at the port is also possible, reducing the time for

terminals to meet port goals,” Mitsui said.

To note,

this development is part of a project encompassing a demonstration of the

hydrogen supply chain from the local production of clean hydrogen to the

consumption point of port container handling equipment, which is partially

subsidized by the New Energy and Industrial Technology Development Organization

(NEDO). In related news, at the beginning of 2024, Japan’s Kobe-Osaka

International Port Corporation launched an initiative to showcase the

operational prowess of hydrogen-fueled cargo handling machinery

The project

will take place at the Kobe International Container Terminal (KICT), managed by

Mitsui O.S.K. Lines (MOL), at the Port of Hanshin.